Any table saw will consist of rotary sawblade that will poke through center of flat worktable. It will be equipped with guides and fences and its primary objective is cutting any solid wood or boards into manageable sizes.

The best table saw on a budget is more than stationary circular saw. It has really earned its present place in various wood shops, due to its ability to do proper cuts safely, quickly and efficiently. Let us look at some of the features of any basic conventional table saw.

Table Saw Features

Following are few features of table saw, which make the saw simpler and more efficient for any kind of project:

- Amps will measure power consumed by saw motor. Indicating higher amps will mean more power for cutting.

- Shaft locks or arbor will immobilize the blade and shaft, thus making it easier to change or replace the blade.

- Blowers and dust chutes will help moving sawdust from your work area.

- With micro-adjust rip fences, you can fine control your work.

- Mobile stands will provide portability and support for the saw.

- Extendable rip fence folding or sliding out will offer expanded capability of rip-cutting when it is needed.

Following are few common uses of table saw:

Ripping

One of the most common uses of table saw is cutting larger boards to smaller pieces, so that it is easier to work. Cutting or ripping of wood to width can be done in parallel to the grain of wood. Always you will run board directly against your rip fence, for avoiding any risk of twisting your board or jamming your saw.

Crosscutting

Crosscutting is normally used for cutting wood to length. Therefore, it has been so named, as you will end up cutting across your wood grain. This kind of work can easily be accomplished with accuracy by using sliding crosscutting table guide.

Bevel cuts

These table saws are having the capability to change blade angle, and allow bevel cuts. You can tilt your saw blade to required angle, after double-checking its accuracy by measuring its angle.

Switch on your saw, then you are ready to feed for normal rips or crosscutting at consistent angle.

Cutting grooves and rabbet

By using table saw, both these common joint cuts can be made easier and also more accurate. You consider both cuts as long and narrow channel in the board. Rabbets will be cut out of far edge of your board, while grooves will be cut more towards center.

Cutting joints

By using table saw, you can create wide varieties of joint cuts, at rabbets and grooves at the outside. As before, sometimes it requires removing blade guard and also riving knife. You must be extra cautious during cutting the joints under these circumstances.

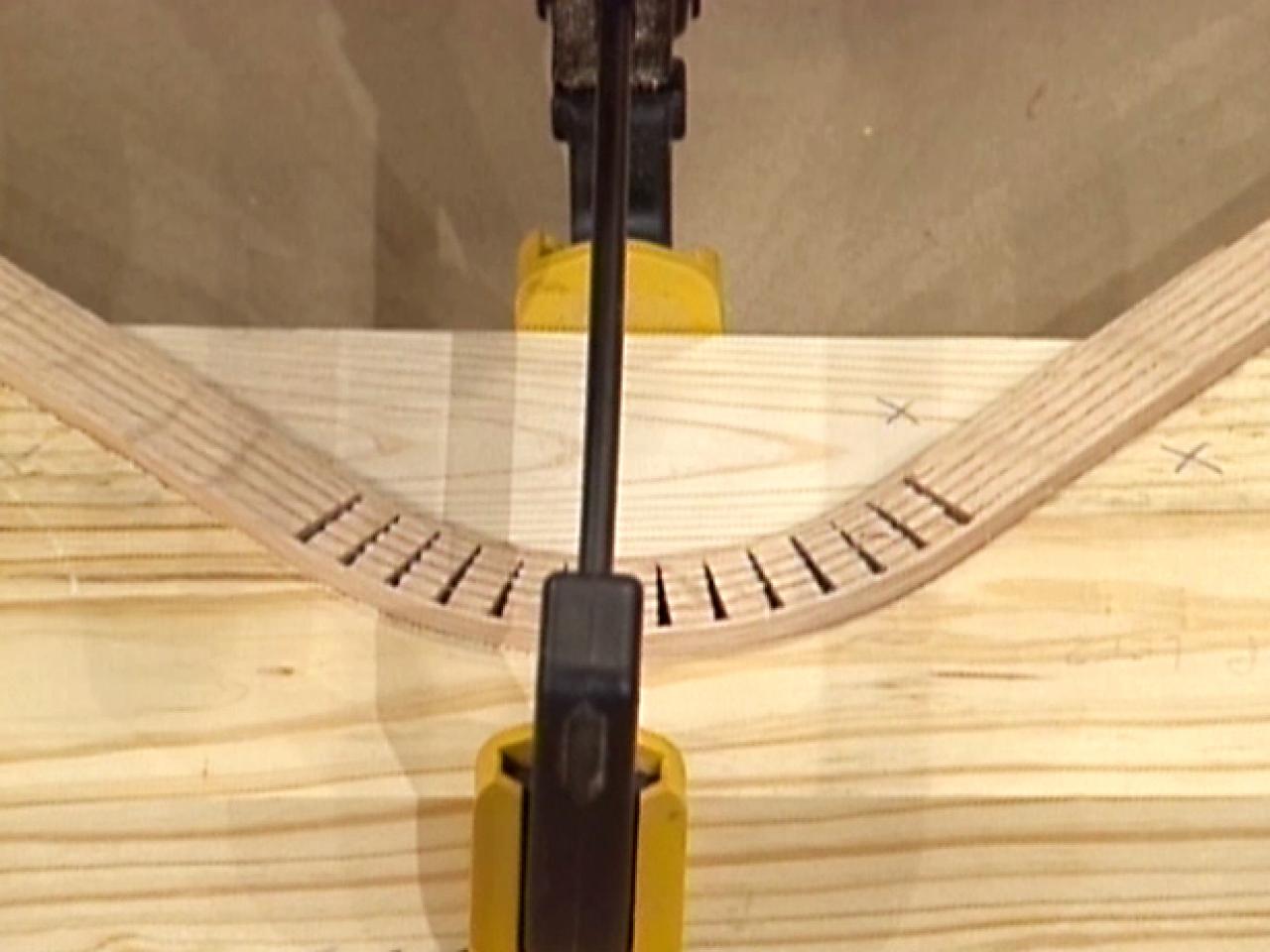

Kerfing

Severing a wood strip with evenly spaced saw cuts will able to provide it with sufficient local flexibility for making tight bend. This is called kerfing, and with this kind of process of getting rid of portions of board can give curve, even to any thick hardwood.