The current COVID-19 crisis has made many people think harder about hygiene standards and how to improve them. However, the simple fact is that they have always been an issue, this is just an extension of basic principles.

Maintaining hygiene standards in industrial buildings is essential to ensure a safe and clean environment for staff. It can also ensure that food, equipment, and products are not compromised when manufacturing. This is especially true if the equipment being made is sensitive.

The standard approach has always been water blasting, steam cleaning, or even vacuuming an area. However, many industrial businesses are now trying dry ice blasting Melbourne, with a lot of success.

What Is Dry Ice Blasting?

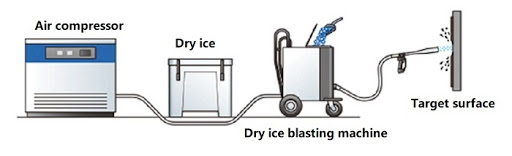

Dry ice machines are designed on the same principles as sandblasters. Of course, as the name suggests, they’ll shoot dry ice instead of sand. The dry ice is ejected as tiny particles, invisible to the naked eye.

These particles hit the surface to be cleaned and effectively freeze it. This causes it to shrink and it will crack. The dry ice then hits the next layer which is warmer and causes the ice to melt. Because the particles are so small, they expand into gas, specifically carbon dioxide.

The process pushes the outer layer off the surface, effectively removing the dirt and leaving the equipment clean, without getting it wet.

Thanks to this almost any surface can be effectively cleaned with dry ice. It will remove grease, paint, tar, dirt, resins, soot, adhesives, oil, decals, and even ink.

Why Is It A Better Option?

One of the best things about dry ice is that it isn’t abrasive. Sandblasters pummel a surface with tiny particles of sand to effectively remove dirt via friction and impact.

But, this process is abrasive and leaves the potential for the surface to be damaged. The damage may not be visible to the human eye but that doesn’t mean it isn’t detrimental to the industrial production process.

Dry ice blasting is also better than water or steam blasting as it doesn’t produce water. That means no extended waiting times for the water to dry and a better success rate on electrical components. Dry ice can be used without fear of damaging electrical components.

It’s also effective at removing mold and helping it to stay away. This is because it leaves no moisture behind that will allow the mold spores to start again.

You can even use it on boat hulls to remove algae and other issues faster than pressure washing.

Eco Credentials

It’s worth noting that dry ice blasting is also an environmentally friendly option. No chemicals are used. Water is simply frozen and broken into tiny particles. It then returns to the air. Not only is there no harm to the environment, but the cost of running a dry ice blasting machine is also surprisingly small. Almost everything it needs can be acquired for very little.