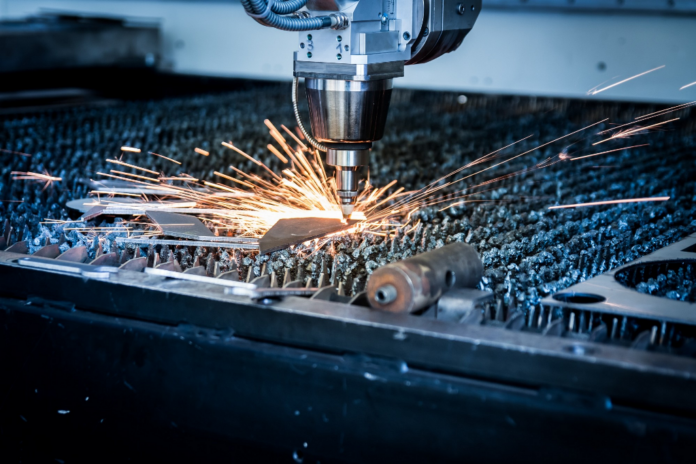

Did you know that the first working laser was invented in 1960? The newest, cutting-edge laser technologies have come a long way since their initial inception. They are making life easier and less expensive for manufacturers in a variety of niches.

Keep reading to learn the ins and outs of laser cutting!

What Industries Can You Find Laser Cutting in?

There are quite a few industries that adopted laser cutting because of its many benefits. The are following are just a few of the industries that are using a reputable laser cutting company to help them save time and money:

Automotive Industry

In the automotive industry laser technology helps design, develop, and manufacture thousands of different parts out of multiple different types of materials. For example, it is sometimes used to cut carriage components to make sure that they fit together correctly. It has also been used to cut airbags.

Electronics Industry

Another industry that is taking advantage of laser technology is the electronics industry for its multiple electronic parts. Everyday parts are becoming smaller and smaller for things such as computers, laptops, cell phones, etc. Laser cutting is able to deliver these more complex and tiny parts without a problem.

Medical Industry

The medical field has seen a rise in laser cutting equipment. High-grade stents are being cut out to improve different medical applications such as kidney stone pain control and birth control. It is also being used for tube cutting.

Advantages

One of the advantages of laser cutting is its flexibility because it does not require changing out tools for each cut that is performed. You can literally use the same setup for multiple shapes as long as they are the same thickness.

Another advantage is how accurate the laser cutting machines are when you compare it to other types of thermal cutting methods. This also allows for higher quality. Even when small accidents occur during production they are so tiny that it’s not even necessary to remove them.

Speed

This type of cutting is a lot faster than traditional mechanical cutting methods. For example, if you compare it to flame cutting or plasma cutting, laser beats them in speed. Keep in mind that the exact speed advantage depends on the power of the laser cutter being used.

Automation

Very little manpower is needed because laser cutting is completely automated. You will still need an experienced operator for the machine but the manpower is not necessary because most machines come with feeding systems and follow-up conveyors to help make the process more automated.

Feeling Like a Cutting-Edge Laser Technologies Pro?

Now that you know more about cutting-edge laser technologies and where they are used, we hope you are starting to feel like a pro on this subject. We are sure that within the next decade we will see even more progress with laser cutting technology.

Did this article teach you something new and helpful today? Keep browsing around for similar interesting reads.