If you are into woodworking in the home – perhaps you like to take things further and build your own furniture – you will have your own workshop set up, complete with your various power tools and other fixtures and fittings. DIY carpentry is a great hobby and the satisfaction of seeing the end result cannot be beaten. Among your kit you will certainly have power and hand saws, drills, sanders and more, and also a variety of basic tools for finishing the wood you are working with. In this article, we are going to talk about type of CNC machines such as CNC wood router, that you may not have heard about, but that is becoming ever more popular in workshop use.

Of course, the machines we are going to talk about here are not the large industrial type of CNC machine – those take up a lot of space and, if you ever get the chance, are well worth watching in operation. Manufacturers have realised there is a market for smaller, workshop- based CNC machines that can help with home DIY and woodworking. So, what is a CNC machine, and how will you benefit from one in your workshop?

What is a CNC Machine?

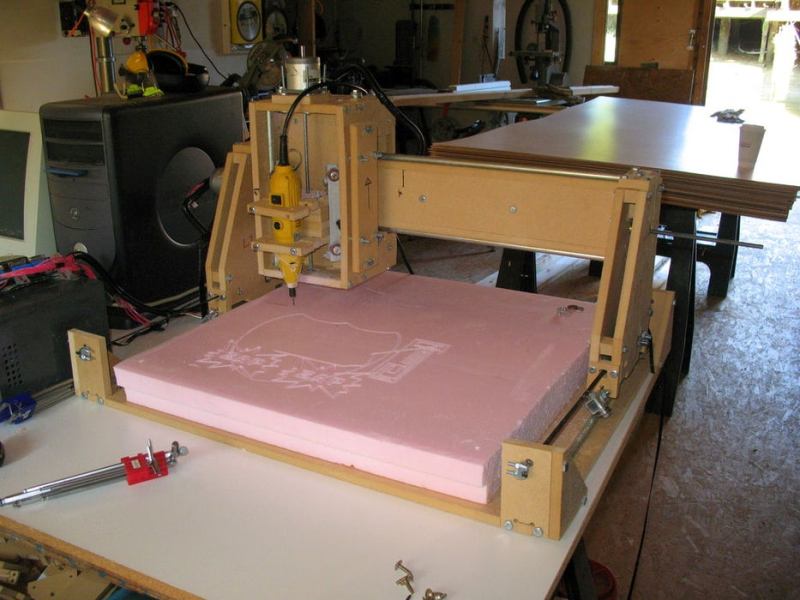

The best way to describe a CNC machine is as a sophisticated, more versatile, computer controlled version of your hand-held router. CNC stands for, quite simply, Computer Numerical Control. The machine itself consists of a number of cutting blades – these differ between types, which we will come to shortly – within a machine head. These are attached to a framework that allows the head to move around. A flat table is for holding the sheet of wood – or perhaps metal up to a point – that you are cutting, and it is programmed by a computer system equipped with Computer Automated Design (CAD) software.

The user – that’s you when you get hold of one – programs or scans into the system the item they want to cut. The CNC software then uses its very clever brain to code the design into numerical instructions, which are used to guide the cutters over the material to be cut in the manner required. This means you simply sit back, and let the machine do the job! You can learn in more detail about the various things a CNC machine can be used for and check out different models, and you’ll soon see just how useful a CNC router can be in your workshop.

What Sort of CNC Router?

For workshop use you ideally want either a bench-top CNC machine, or one that is stand alone but small enough to fit in the corner of your workshop. There are many to choose from, and the more versatile are those that offer greater levels of cutting ability. If you choose a bench-top model – and many home woodworkers and DIY enthusiasts recommend this type – this will easily be the more versatile option, and will still be very capable. There are different types of cutting blade that come with these machines, too, so you should certainly do your homework before deciding on the one that is for you.

If you do want a bigger machine, make sure you have the space to fit a stand-alone CNC machine in your workshop. These are available for domestic use, but be aware they are more costly than the alternative. The advantage of a CNC machine is, more than anything else, amazing accuracy and quality of finish. The tolerances you are dealing with when you use one of these machines are minimal, and you will certainly end up with a cut sheet that you are very happy with.

For more versatility in your woodworking, check out CNC machines, and enjoy greater precision all-round.